u-blox's Cellular Module Exit

In January 2025, u-blox, the Swiss manufacturer of wireless semiconductors and modules, surprised many by announcing its exit from the cellular IoT modular market. This strategic decision affects thousands of IoT projects worldwide, as the company shifts focus to its Locate (GNSS) and Short-Range businesses (Wi-Fi and Bluetooth modules).

With more than 200 employees and revenue of CHF 27 million (USD 30 million) in the cellular division, u-blox leaving this market creates significant challenges for companies that use their cellular modules in their products.

Embedded Tech Podcast | Episode 1

TL;DR

- Swiss wireless manufacturer u-blox will stop making cellular IoT modules in 2025.

- This affects thousands of IoT projects worldwide.

- Companies using u-blox cellular modules should immediately secure supply through last-time buys, evaluate replacement opportunities, and consider both hardware and software migration challenges.

- This shift in the market highlights how important it is to design for component resilience, keep an eye on industry trends, and plan for future risks.

- With increasing geopolitical influences on chip supply chains, businesses now need to consider more than just tech specs when choosing components.

- Adaptable companies can turn this disruption into a competitive advantage through thoughtful product redesign.

Contents

At ByteSnap Design, we have 17+ years of embedded electronics experience. Our team have compiled our top tips and insights for IoT companies to help navigate this issue, based on our previous experience dealing with similar component obsolescence challenges.

The u-blox Exit: Context and Market Implications

u-blox’s decision to leave the cellular market comes as competition increases, particularly with Chinese manufacturers who hold a significant market share and competitive prices. The Swiss company reported a loss of over CHF 15 million (USD 16 million) in the first half of 2024, showing how tough it is, even for well-established companies in this sector.

This market consolidation reflects broader trends in the semiconductor industry. Geopolitical factors and pricing pressures are reshaping supply chains. For product developers, it serves as a reminder that even the most established component suppliers can pivot and affect your product.

Immediate Actions for u-blox Cellular Module Users:

1. Securing Supply Through Last-Time Buys (LTBs)

The first thing your can do is protect your supply chain through last-time buys (LTBs). For industrial customers with low volume requirements, this is fairly straightforward, and purchasing five years’ worth of stock is a good option. However, high-volume manufacturers will likely face major cashflow challenges if u-blox modules represent a substantial part of their bill of materials (BOMs).

Managing u-blox Module Obsolescence

2. Evaluating Replacement Opportunities

While its important to secure supplies quickly, this challenge also presents you with an opportunity to improve your product. Rather than simply looking for direct replacements, consider whether this is the right time to upgrade your product features. Ask yourself:

- Will you benefit from migrating to newer cellular standards (4G/5G)?

- Would different frequency bands offer better compatibility for your international markets?

- Will a new module deliver power savings or higher data rates?

- Is this an opportunity to include new features or functions in your product?

For newer products, this obsolescence challenge could can kick-start product improvements that will ensure your product remains useful in the future market.

Technical Challenges in Module Migration:

Software migration can often be more expensive than hardware redesign, particularly for complex products with advanced connectivity requirements.

Hardware Considerations

Size is going to be a key challenge. For smaller products, it can be tough finding a replacement that matches u-blox’s compact size, meaning it may be necessary for you to redesign your PCB.

Key hardware considerations include:

- Power supply requirements and their effect on battery life

- Compliance testing requirements for new modules

- Antenna design and RF performance

- Thermal characteristics and heat dissipation

- Mechanical mounting and vibration resistance

- Environmental tolerance (temperature, humidity, etc.)

For products in regulated industries, hardware changes may require re-certification. You will need to factor in adding both time and cost to the migration process.

Software Integration Complexities

Module manufacturers claim perfect performance, but the reality is a little different. Over the years at ByteSnap, we’ve seen many modem issues, including numerous firmware updates for bugs.

Key software considerations include:

- Driver compatibility and development

- Network handover behaviour differences between manufacturers

- Reliability testing under various network conditions

- Protocol stack compatibility and performance

- Power management behaviour

- Security implementation differences

- Firmware updates and how they work

For established products, it might be better to select replacement modules with a proven track record rather than going for the very latest offering.

Selecting Sustainable Replacements

When assessing replacement cellular modules, you should consider both the immediate fit and how they’ll work in the long-run. Here are some important technical and strategic considerations:

It’s worth noting that the cellular module market has already shrunk, and may well do so further. With Chinese manufacturers holding a large market share through their competitive pricing, this has made it harder for traditional suppliers like u-blox to turn a profit. Further well-established companies may decide to make a similar exit in the future.

Case Study: Successfully Navigating Component Obsolescence

Challenge

The manufacturer would have to cease production because their main microcontroller was unavailable. With high volume requirements and competitive market positioning, they couldn’t afford extended downtime or significant cost increases.

Our Approach

- Conducted a complete hardware redesign around an alternative microcontroller, selected for long-term availability and supply chain resilience

- Updated the code to support the new platform, maintaining existing functionality, while improving performance where possible

- Managed compliance testing and certification

Outcome

The client gained a successful back-up design– even after the supply chain pressures improved, they benefited from having two compliant designs they could manufacture based on component availability. This flexibility gave their product the competitor advantage during subsequent component market fluctuations.

During the post-COVID chip shortages in 2022, ByteSnap helped many clients face their obsolescence challenges. In one notable case, we assisted a home appliance manufacturer. This company produced over 100,000 units annually, but faced a challenge when their critical microcontroller was no longer available.

Future-Proofing Against Obsolescence:

Monitoring Industry Trends

Signs in the market that can help companies prepare for future disruptions:

Market Signs

- Industry mergers and company buyouts

- Margin pressure in specific technology segments

- Product roadmap changes or lack of updates

- Shifts in leadership or strategic focus

- Geopolitical factors affecting chip manufacturing

- Changes in customer support quality or response time

- Financial performance warnings or analyst downgrades

For SMEs with complex BOMs, it can be tough to keep track of every supplier. However, by focusing on critical components and staying up-to-date with industry news, this can help you spot early warning signs.

Design Strategies for Resilience

Several design strategies can reduce the risk of obsolescence:

Design Strategies

- Using socketed or modular designs where practical

- Selecting components with established longevity programmes

- Maintaining design flexibility to accommodate alternatives

- Building relationships with several good suppliers

- Implementing abstraction layers in software to simplify hardware migrations

- Designing with back-ups in mind from the start

- Regularly checking for risks for critical components

- Maintaining clear documentation to make future redesigns easier

Risk Mitigation Strategies

Risk mitigation Strategies to help avoid the risk of obsolescence.

Avoid the Risks

- Regular supply chain audits and resilience assessments

- Establishing obsolescence management as a formal business process

- Developing relationships with specialist component brokers

- Maintaining a component life cycle database for critical parts

- Training engineering teams on obsolescence management principles

- Agreements with suppliers regarding end-of-life notifications

- Regular technology roadmapping aligned with supplier roadmaps

- Joining industry standards groups

The Changing Landscape of Component Selection

The global semiconductor industry is rapidly evolving, with geopolitical factors increasingly affecting supply chains. We’re now facing many political issues, particularly around tariffs and chip fabrication locations. The heavy dependence on Taiwan poses some risks, and we are likely to see significant market movement over the next decade, regarding who makes chips and where chips.

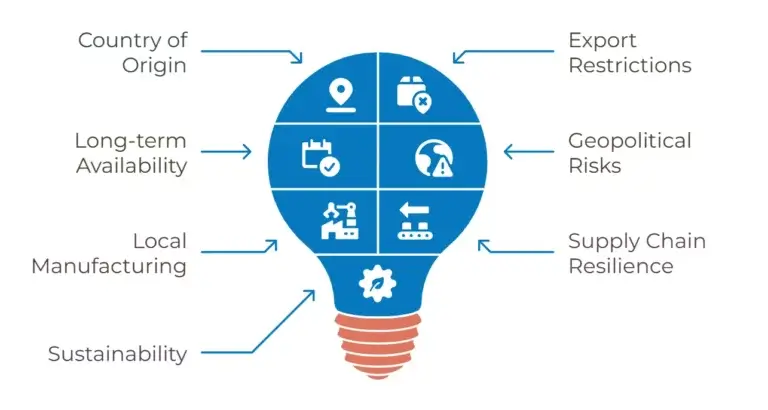

These shifts are changing how design decisions are made. Before, engineers selected simply the best technical option. Now, when selecting a part you have to consider:

The Role of AI in Choosing Parts

Looking forward, AI tools may play an increasing role in selecting parts and managing obsolescence. While it’s still early days for artificial intelligence, there are already emerging use cases, including:

- Predictive analytics for component life cycle forecasting

- Automated identification of alternatives

- Supply chain risk assessment and visualisation

- Early warning systems for potential obsolescence

- Design optimisation for supply chain resilience

Conclusion: Adaptability as Competitive Advantage

The u-blox cellular exit serves as a reminder that even the big companies in the electronics industry must continuously adapt within the market. For businesses building IoT products, this highlights the importance of designing with component obsolescence in mind from the beginning.

Success requires balancing immediate design goals against long-term sustainability. By planning ahead, companies can turn potential supply chain disruptions into opportunities for product enhancement and to help their product stand out in the market.

At ByteSnap, we continue to support our clients through these challenges. We provide both immediate solutions to obsolescence challenges and strategic guidance for building more resilient products through redesign services.

As the electronics industry evolves, your company’s adaptability is crucial, if you wish to grow in the IoT market.

Key Takeaways:

- Act quickly to secure supply through last-time buys for affected u-blox modules

- Consider whether this is an opportunity to improve your product’s features

- Balance technical compatibility with long-term strategy when replacing parts

- Design for resilience by incorporating modularity and second-sourcing principles

- Establish future obsolescence management processes as part of business operations

- Monitor industry trends for your critical components, to catch early warning signs

- Consider both technical and geopolitical factors when selecting a component

Need Help with Your product?

FAQs - u-blox Cellular Phase Out: How to Save Your IoT Product

1. What's happening with u-blox and their cellular modules?

u-blox, the Swiss manufacturer, is exiting the cellular IoT module market in 2025. This means they’ll stop making these modules, which affects loads of IoT projects globally. Instead, they’re focusing on their Locate (GNSS) and Short-Range (Wi-Fi and Bluetooth) businesses.

2. Why is u-blox stopping the production of cellular modules?

Due to increased competition, especially from Chinese manufacturers offering very competitive prices. u-blox reported a loss in their cellular division, showing the market is proving difficult even for long-standing companies.

3. I use u-blox cellular modules. What should I do right now?

The first thing to do is to secure your supply. Look into last-time buys (LTBs) to get enough modules to keep you going. At the same time, start looking at other replacement modules for future designs. Lastly, consider whether it’s time for a re-design to upgrade your current product features.

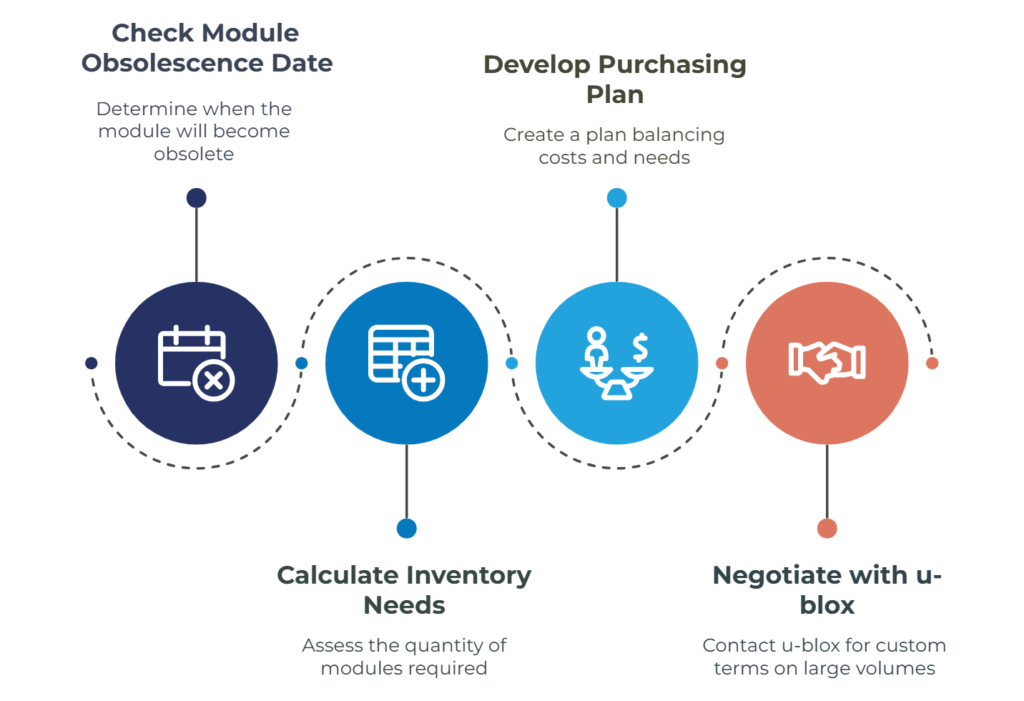

4. What's a "last-time buy" (LTB) and how do I do it?

A last-time buy is when you purchase as much of a component as you can before it becomes obsolete. Figure out when your specific u-blox module is going out of production, calculate how many you need, and then create a purchasing plan. Contact u-blox directly to discuss your requirements, particularly if you need a large quantity.

5. Should I just find a direct replacement for my u-blox module?

Not necessarily. This obsolescence issue is an opportunity to improve your product. Think about whether migrating to newer cellular standards (4G/5G), using different frequency bands, or adding new features would benefit you.

6. What are the main challenges when switching to a new cellular module?

There are two main areas of concern: hardware and software. Hardware challenges include size differences, power supply requirements, antenna design, and compliance testing. Software challenges include driver compatibility, network behaviour, protocol stack performance, and security. Software migration can often be more expensive than hardware redesign, especially for complex products.

7. What should I consider when selecting a replacement module?

Think about both technical and strategic factors. Technically, consider size, pin compatibility, power usage, cellular standard support, and security features. Strategically, think about geopolitical factors affecting the supplier’s supply chain, their commitment to ongoing support, manufacturing capacity, and roadmap alignment with your product life cycle.

8. How can I protect my product from this happening again in the future?

Future-proof your designs! Use modular designs, select components with longevity programmes, keep your design flexible, build relationships with multiple suppliers, and implement abstraction layers in your software. Also, monitor industry trends to spot early warning signs of potential obsolescence.

9. Component geopolitical factors? What do you mean?

The global semiconductor industry is changing, and geopolitical issues like trade restrictions and where chip fabrication plants are located, are becoming increasingly important. You now need to think about a component’s country of origin, potential export restrictions, and supply chain resilience when making selections.

10. Can ByteSnap Design help me with this u-blox situation?

Yes! ByteSnap Design specialises in helping companies navigate component obsolescence and product redesign. We can provide solutions to your u-blox challenges and offer strategic guidance for building more resilient products. Schedule a call to discuss your specific needs.

Founded in 2008, ByteSnap Design is an award-winning embedded systems design consultancy, offering a comprehensive range of services across the electronic product development lifecycle.

A highly skilled team of over 40 hardware and software engineers, our expertise spans several sectors, including IoT, automotive, industrial, medical, and consumer electronics.

The engineering consultants on the ByteSnap Editorial Team share their knowledge and practical tips to help you streamline your product development and accelerate designs to market successfully.

With their deep technical expertise and practical experience, they aim to provide valuable insights and actionable tips to guide you through the complex world of electronic product design and development, to help you bring innovative, reliable, and secure electronic products to market quickly and cost-effectively.