This guide on Industrial IoT explores the core solution components of IoT device design (electronics, embedded firmware, embedded systems, microcontrollers, sensors, and actuators), machine-to-machine connectivity, data analysis, machine learning, artificial intelligence, and automation.

Table of Contents

Introduction - What is Industry 4.0?

The 4th industrial revolution, referred to as Industry 4.0, is pretty much part of our daily lives, with connected devices changing the way we live and work.

Industry 4.0 is a concept that combines the physical, digital, and biological worlds.

Technology is used to integrate people, business processes, data, and the Industrial Internet of Things (IIoT), at an unprecedented level of efficiency.

Many companies are progressing Industry 4.0 design and development projects to:

- Create new business models and opportunities for sustainable growth.

- Increase operational efficiency (using smart data) and higher productivity.

- Improve productivity through greater flexibility of work models.

- Lower costs through optimisation of processes by linking machines or systems.

- Enhance customer satisfaction through personalised products and services.

A survey by Deloitte referenced in a Forbes article titled Industry 4.0 and the future of supply chains, identified the top 10 technologies that are driving Industry 4.0 supply chain solutions.

These top 10 technologies are also the core components that span many of the industrial digitisation and transformation solutions. In order of influence, they are:

- IoT (Internet of Things)

- AI (Artificial Intelligence)

- Cloud Infrastructure

- Big Data/Analytics

- Nanotechnology

- Advanced Robotics

- Sensors

- Blockchain

- 3-D Printing

- Augmented Reality

- Quantum Computing

- Edge Computing

The most influential of all technologies, according to the Deloitte surveyed business leaders, is the Internet of Things.

IoT, or more specifically IIoT development projects, will include:

- Electrification and connectivity of IoT devices, products, and machines

- Design and development of IoT devices, products, and machines including:

- IoT device electronics

- IoT embedded firmware

- IoT embedded systems

- IoT microcontrollers and IoT sensors

- IoT actuators

- Data analysis, machine learning, artificial intelligence, and automation

Industry processes that will be digitised and transformed

IIoT seeks to digitise and electronically connect industrial machines, devices, plants, and other equipment with one another to significantly improve or transform business processes.

IIoT makes possible all kinds of new products, services, and solutions to enhance and transform industry processes including such items as:

- self-driving connected vehicles;

- telematic on-road and off-road solutions that combine wireless communications, location technology, and in-vehicle/machine electronics;

- high-tech hospitals providing care remotely;

- disaster relief operations worldwide; remote monitoring systems for critical infrastructure such as power grids; etc.

IoT is transforming the lives of many people. For example, solutions like smart homes can automatically adjust their lighting and temperature based on current weather conditions outside.

Industry can extend the boundaries of IIoT services and solutions by integrating consumer-based IoT-connected devices and products too.

With the success of smart city initiatives across the globe, there has been increased interest in IoT technologies from both the public and private sectors.

The options are endless in IIoT development. It involves using technology in innovative ways and connecting various systems to enhance their collaboration.

Industry 4.0 and IIoT are transforming the way many businesses are operating and creating competitive advantages as they evolve and build new processes. It is bringing intelligence to connected devices, products, machines, factories, and assets.

A recent article by McKinsey, titled capturing the true value of industry 4.0, highlighted that for industry 4.0 solutions, that are implemented successfully, it is not uncommon to see 15 to 30% improvements in labour productivity, 10 to 30% increases in throughput, 30 to 50% reductions in machine downtime, and 85% more accurate forecasting.

Electrification and connectivity of the IoT devices, products, and machines

The conversion of a machine or system to the use of electrical power is referred to as the electrification of that item. Standalone or disparate products that are digitised and electrified can become intelligent and be connected to the internet or the internet of things.

A car may be an IoT machine, but a simple bicycle can be too. A bike may have sensors that connect to onboard MCUs that send sensor information to the rider’s app on their mobile phone that then communicates this information externally.

This is a simple example but from an Industry 4.0 perspective indicates that almost any device, product, or machine can be electrified and digitised to become part of the industry 4.0 solution.

M2M electronics and connectivity solutions for device-to-device, product-to-product, or machine-to-machine communications, as well as power management systems for industrial automation, are all part of industry 4.0 solutions.

If you’re new to the idea of IIoT, you might be wondering how it’s different from your standard connected device. IIoT makes use of electrification and connectivity. Electrification refers to any process that involves energy conversion, while connectivity refers to the ability of devices like those in Industry 4.0 to connect with each other.

The next step is to ensure that your device has the right machine-to-machine (M2M) electronics and connectivity. This includes choosing the right chipset, antenna type and antenna placement, as well as any other hardware connections.

M2M technology is now available in many different forms, including cellular networks (3G/4G/5G), satellite networks, Wi-Fi, and Bluetooth Low Energy (BLE) technology.

Design and development of IoT devices, products, and machines

An IIoT device, product, or machine, can therefore be created through the digitisation, electrification, and connectivity of what may have previously been a disparate product, or by designing and developing a specific internet-connected device.

The main core components when creating the IoT device are the IoT device electronics, embedded firmware, embedded systems, microcontrollers and sensors, and actuators.

IoT device electronics

Within the IoT device will be the embedded hardware and electronics. This includes everything from the electronic circuit boards to the control interfaces and panels, to LEDs and buzzers, through to the device display/s and power supplies.

IoT devices are often mobile and can’t connect easily to external power sources, so electronic designers will select components that use little power.

The supporting electronic designed printed circuit board will need to support the sensors, connectivity, and power management and carefully consider the attributes of the IoT application.

For example, IoT devices can be extremely small, and this may require the use of low-cost multilayer PCBs and high-density components. Volume applications will require low-cost IoT components. Hazardous environments may require the use of ATEX components.

Where products need to flex, for example in wearables, flexible PCBs will need to be used. Careful consideration is required throughout the IoT device design which may not be required when creating a typical electronic circuit board.

Also, the power supply for the IIoT device will be carefully chosen – again, based on the device’s application.

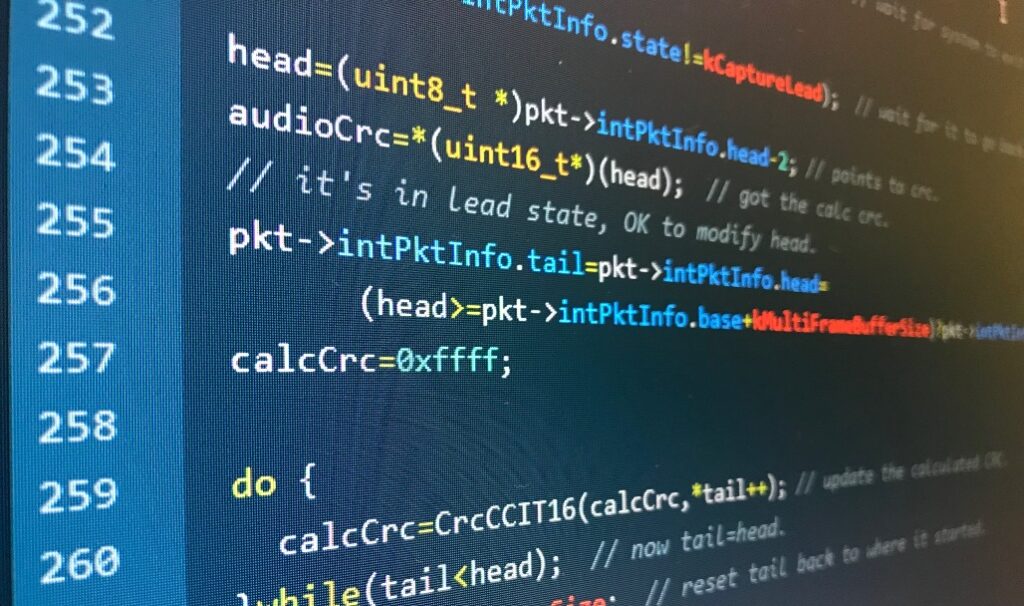

IoT embedded firmware

At the heart of an IoT-connected device or connected product/machine is embedded firmware.

This is the programming code that resides in the electronic memory of the various connected products that enables drivers for microprocessors and hardware interfaces, provides intelligence for operations and at the edge connectivity and for the security of the IoT connected products.

This is a very important software component since it is responsible for the reliability and security of the product. It is the firmware that makes the product work.

IoT-connected devices are complex pieces of equipment with multiple functions and high-performance requirements.

As a result, they require complex embedded software. Consequently, the development of embedded firmware requires a lot of time, resources, and expertise. This is a challenge that manufacturers face when developing new IoT-connected products or updating existing ones.

IoT embedded systems

An IoT embedded system is the hardware and software of the connected devices, products, and machines developed in support of a specific IIoT function or functions.

For example, an IoT-embedded system may be designed to monitor and report on environmental conditions.

The hardware may consist of an external sensor device that is connected to the embedded system through a wireless communication link.

This connection would allow the embedded system to communicate with the external sensor device.

The embedded system would then convert the environmental data received from the external sensor device into a useful form for the end user.

There are many different types of IoT embedded systems, which can be classified into two broad categories:

- Embedded systems that are built using commercial off-the-shelf (COTS) hardware.

- Embedded systems that are designed from scratch using a standard hardware platform.

- Embedded systems that are built using COTS hardware are typically very cost-effective. However, they also usually have limited capabilities in terms of the number of sensors and actuators that they can support.

On the other hand, embedded systems that are designed from scratch using a standard hardware platform typically have the flexibility to support a large number of sensors and actuators.

Embedded systems span a range of capabilities and can be simple – such as a lighting control system – or complex – an intricate process control or guidance system, for instance.

IoT microcontrollers (IoT MCUs) and IoT sensors

IoT MCUs are the processors and controllers that reside in IoT devices and products.

In conjunction with the embedded firmware and the embedded software, they are programmable devices with multiple input and output interfaces used for sensing, monitoring, and controlling IoT smart devices, products and machines.

For example, an IoT MCU may be combined with an IoT sensor that senses a condition (e.g., something is hot/cold, someone spoke, something moved, a switch was pressed, the carbon monoxide level has changed, and so on) and the MCU processes the information sensed and invokes an action, as designed in the electronics hardware, or programmed in the software or firmware, resulting from the state sensed.

There is a huge array of IoT sensors that can be used for sensing temperature, distance, sound, magnetism, water, air, pressure, speed, images, levels, flow, chemicals, motion, light, smoke, humidity, and many other areas.

The IoT MCU has become one of the key components of IoT products due to its ability to perform many functions and its cost-effective implementation.

However, a single IoT MCU is usually not enough for large-scale IIoT applications.

Multiple IoT MCUs are used to control the operation of each IoT product. The IoT MCUs communicate with each other to achieve the desired IoT application functions.

IoT actuators

IoT actuators are used for controlling a wide variety of industrial applications including air conditioning, business and domestic appliances, and heating.

IoT actuators are connected to the cloud or a server and can be powered either by a wired connection (USB, Ethernet) or a wireless connection (Bluetooth, WiFi).

The most commonly used IoT actuator is the relay, a device that controls/switches the flow of electricity. This is the simplest form of IoT actuator.

The main features of IoT actuators are self-powered, high accuracy, low cost, easy installation, robust design, high reliability, energy efficiency and durability.

There are many different types of IoT actuators:

- An electrical actuator operates by converting electrical energy into mechanical energy. The actuator has the capability of storing and releasing mechanical energy in a controlled manner to provide motion control or position control for a variety of devices such as servo motors and valves.

- The thermal actuator is operated by heating and cooling mechanisms.

- A magnetic actuator is controlled by changing the direction of the magnetic field. The magnetic actuator is used to pull or push objects, such as wires, rods, and springs.

- A hydraulic actuator operates by forcing pressurised fluid through a piston and cylinder arrangement.

- A pneumatic actuator uses compressed air or nitrogen gas to produce a pushing or pulling force.

- An IoT actuator takes an electronic signal and combines it with an energy source and converts it into motion. Thermal, Magnetic, Electrical, Hydraulic and Pneumatic actuators are available.

Electronics, embedded firmware, embedded systems, MCUs, sensors, and actuators, along with fast and secure communication networks, combine to create digitised, electrified, and transformative connected IIoT solutions.

For example, with over one hundred MCUs in a modern digital vehicle, whether on-road or off-road, they have become IoT machines.

They have sensors that connect via high-speed connections or communication buses within the machine (CAN FD for example) that can sense an event and then the MCU processes this and this event may be sent to an external control centre or another IoT device, product or machine to invoke a wider action.

Data analysis, machine learning, artificial intelligence, and automation

Data, big data, analytics, machine learning, artificial intelligence, and automation will play a vital role in developing new efficient and productive Industry 4.0 solutions.

- Data is the information presented by the various components within the industry 4.0 and IIoT solutions. For example, sensors will present data on a machine’s current status, while actuators will present data on how to operate the machine based on the status of the machine.

- Big data relates to the large array of information that is available in the digital world. The most obvious source of big data is the internet itself as it generates a massive amount of information every second. It can also be found in social media platforms, financial transactions, health care records and much more. This external information can be used by the industry 4.0 solution to benchmark and obtain vital information that improves machine learning and decision-making.

- Machine learning involves the development of algorithms that can learn from the data and big data. It is one of the most rapidly growing areas of computer science and has applications in many fields including pattern recognition, computer vision, speech processing, robotics, natural language processing, bioinformatics, economics, and finance.

- Artificial intelligence (AI) is bringing machine and computer-based intelligence, which often emulates human intelligence, into digitised industrial connected process-centric solutions. AI will play a crucial role in the development of new industrial applications which will be supported by the growth of AI-powered hardware, software, and services. AI will have a significant impact on the future profile of the workforce.

- Process automation is the use of computer software to automate or streamline a business process.It can include the use of technology such as artificial intelligence, robotics, and machine learning. Automation has many benefits increasing efficiency, reducing costs, improving customer service, and helping to comply with regulations.

The IIoT is a system of connected machines, devices, vehicles, and people, providing data about the physical world. The IIoT includes the collection, analysis, interpretation, and presentation of this data in an industrial environment.

The data captured is analysed and the learning, the machine learning, is used to adjust, improve and optimise the industry 4.0 working processes and to act on the information it presents.

Decisions and actions resulting from data analysis may be automated, made by humans, or use artificial intelligence for continuous learning and adjustments.

The modern Industry 4.0 environment is reliant on data to understand the adjustments that need to be made to improve performance, be more productive, enhance efficiency and reduce costs.

Summary

Industry 4.0 is the next step in the digital transformation of the industrial sector.

IIoT is the technology that will connect everything and is bringing electrification and connected intelligence to devices, products, machines, factories, and assets.

Data, big data, analytics, machine learning, artificial intelligence, and automation are all key components in developing new industrial solutions.

All of these areas combine to create a more efficient, effective, and productive industry and business.

These projects, often transformative, help users to improve customer satisfaction, increase productivity, lower costs, increase operational efficiency and productivity, and increase employee satisfaction.