Maximise Quality withByteSnap's ElectronicProduction Testing Services

For transfer to manufacture efficiency

New: SnapPro IQ intelligent testing and IP protection tool - see below for details

Is unreliable product testing putting your electronics at risk?

At ByteSnap, we understand the challenges of transfer to manufacture and of ensuring your electronic products meet the highest quality standards.

Our comprehensive electronic production testing services help you avoid costly recalls, protect your reputation, and get your products to market faster.

In today’s competitive market, a single defect can lead to:

- Expensive product recalls

- Damage to your brand’s reputation

- Lost time and revenue

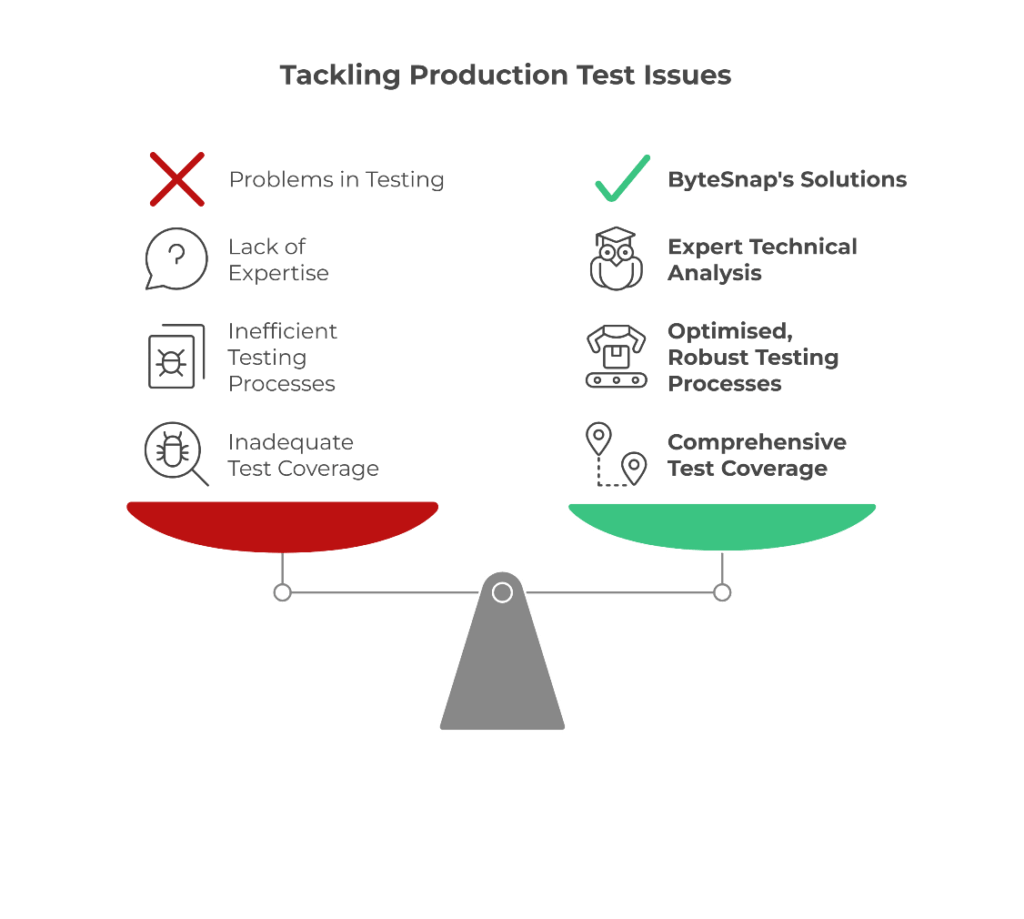

Many companies struggle with:

- Expensive product recalls

- Damage to your brand’s reputation

- Lost time and revenue

To avoid these pitfalls, it’s best to work with an expert electronic production testing services provider.

ByteSnap's electronic production testing services provide:

- Comprehensive test coverage up to 100%

- Custom-designed test rigs and fixtures

- Expert analysis and optimisation of your testing processes

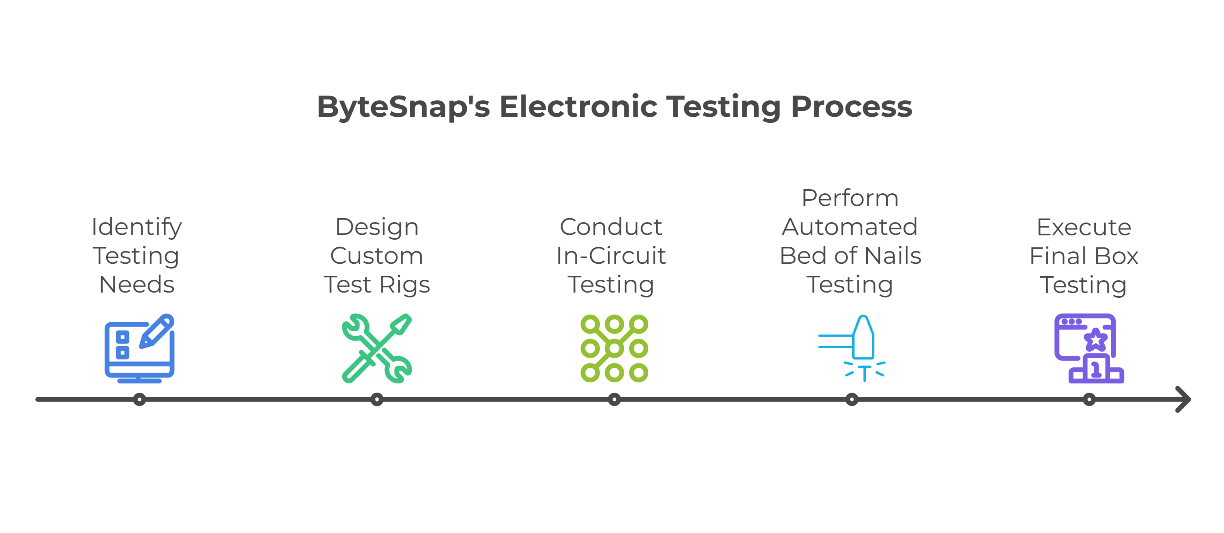

Our proven approach combines In-Circuit Testing (ICT), Automated Bed of Nails Testing and Final Box Testing.

With nearly twenty years of experience in electronic design and testing, ByteSnap is your trusted partner in ensuring product quality.

Our multi-functional team of hardware specialists, software engineers, and production test experts work together to deliver tailored solutions that meet your specific needs.

How it works

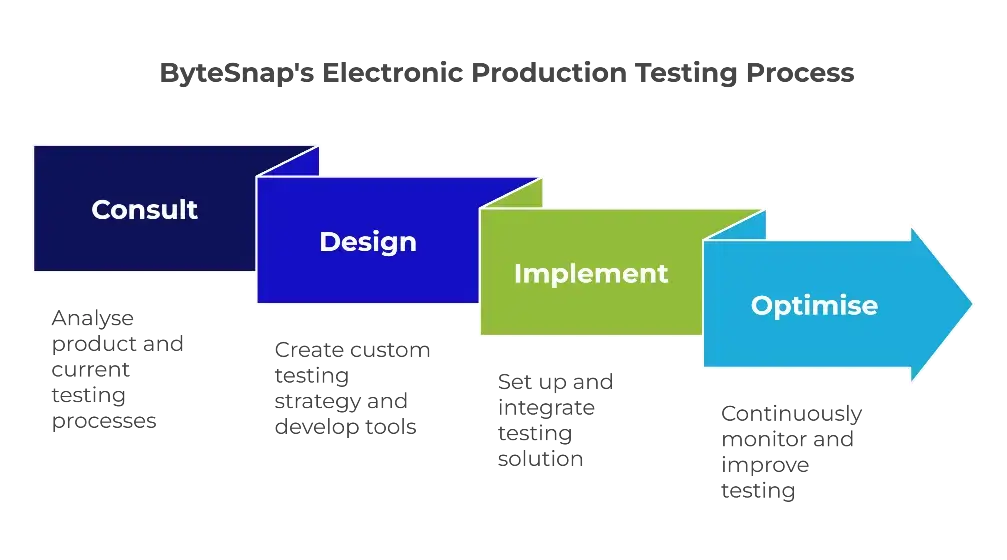

- Consult: We analyse your product and current testing processes

- Design: We create a custom testing strategy and develop necessary hardware/software

- Implement: We set up and integrate the testing solution into your production line

- Optimise: We continuously monitor and improve the testing process

Don’t let defects compromise your product quality. Work with the experts at ByteSnap for a comprehensive electronic production testing solution.

With ByteSnap's electronic production testing services, you can:

Achieve up to 100% test coverage

Reduce field failures and product recalls

Accelerate time-to-market

Enhance your brand’s reputation for quality

However, without robust testing:

Defective products may reach customers

Your brand could suffer irreparable damage

You risk losing market share to more reliable competitors

Ensure your electronic products meet the highest quality standards. Trust ByteSnap’s expertise in electronic production testing to safeguard your success.

New SnapPro IQ: Intelligent Testing & IP Protection

Introducing SnapPro IQ, ByteSnap’s powerful automated PCBA test solution that streamlines quality control while protecting your intellectual property.

Assign unique identifiers to each printed circuit board assembly, capture comprehensive test data and track production history in a secure cloud database.

With SnapPro IQ, you can prevent hardware cloning and maintain complete control over your products, regardless of where they’re manufactured.

SnapPro IQ delivers enterprise-level testing intelligence for small to mid-sized electronics manufacturers without requiring massive investment. The system’s detailed data insights allow you to quickly identify root causes when defects occur, minimising production delays and preventing faulty PCBAs from reaching end customers.

Already proven effective across various production environments—from small batches to high-volume runs—SnapPro IQ can be customised to meet your specific testing requirements, ensuring greater accuracy, faster issue resolution, and prevention of costly failures.

Why use SnapPro IQ?

- Prevent IP Theft – Secure licensing prevents unauthorised cloning of your hardware

- Real-Time Quality Insights – Capture and log detailed PCBA data for immediate analysis

- Enhanced Defect Detection – Identify issues before products leave the factory

- Root Cause Analysis – Quickly pinpoint and resolve manufacturing problems

- Cloud Integration – Access secure production data through third-party quality management systems

- Scalable Solutions – Customised for both small batch and high-volume production runs

- Production Control – Assign manufacturing quotas to contract manufacturers that cannot be exceeded

- Cost Reduction – Minimise expensive rework and eliminate potential field failures

- Streamlined Efficiency – Reduce overhead costs while maintaining superior quality

“Our approach focuses on designing for test and manufacture from the ground up. This strategy ensures that we can access necessary test points during production, implement a comprehensive testing strategy without compromising the product’s design, and prevent costly redesigns or manufacturing issues down the line.”