ATEX Product Design Services | Intrinsic Safety Specialists

Find out how ByteSnap can develop your electronics to pass strict certifications

Award-Winning Embedded Electronics Design Team

Expertise for All Stages of Your Product Development

Intrinsic Safety for Zone 0 Environments

Work With Experts To Eliminate ATEX Compliance Risks That Could Shut Down Your Production Line

ByteSnap’s engineering specialists have advanced knowledge of intrinsically safe product design, from Technical Specification to IECEx schemes and ATEX Certification.

Whether you’re just looking for an initial feasibility study or complete product development, our team has the solution.

Previously, we have designed products for use in potentially dangerous environments, including a Zone 0 Biogas Analyzer. Beyond the design itself, we have experience with ATEX regulatory authorities, and will save you money and time on documentation and testing.

You’re in Safe hands with ByteSnap Design.

Our experience extends throughout our team, and we work closely with our clients to fully understand and develop a design that meets all business and technical requirements.

We have over 16 years’ experience delivering high quality products with competitive timeframes and budgets, in many different sectors.

ByteSnap offers design expertise for all stages of product development, from Technical Specification to Long Term Support.

With a fully integrated hardware and software team, we are the one-stop solution for any project.

We specialise in Intrinsically Safe Design

There are many ways to make equipment safe for use in hazardous environments, including encapsulation and explosion/flame proof enclosures. However, another key method is through intrinsic design. This can reduce material costs and increase flexibility in dimensions.

There are many situations where intrinsic safety is the optimal approach, including handheld devices and industrial sensors. We have extensive experience in Low Power Design, including wireless products.

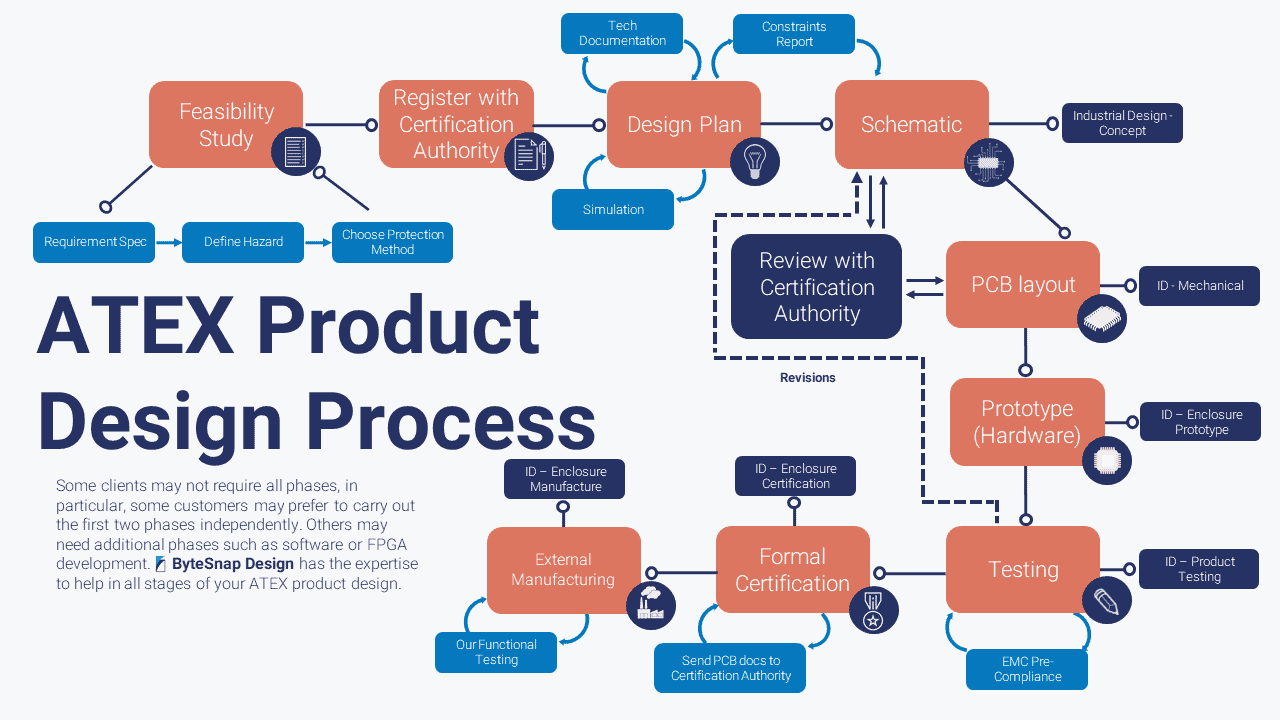

TO PRODUCE A SUCCESSFUL ATEX PRODUCT DESIGN WE FOLLOW THIS PROCESS:

The ATEX Product Design process differs considerably from other electronic devices due to the extra considerations, for example the Industrial Design (ID) steps shown on the diagram are essential to ensure an appropriate Ingress Protection (IP) rating is achieved so explosive particles cannot enter the device.

ByteSnap is experienced in reducing power across the device without compromising functionality, and has been through the regular reviews and checks with the certification authority, and this experience and knowledge reduces time-to-market.

What categories of products require ATEX conscious design?

ATEX is an acronym for ATmospheres EXplosible and refers to any hazardous environment containing gases or dust particles that carry an explosion or fire risk – for example, petrochemical plants or flour mills.

Due to the higher risk to workers and equipment, all electronic devices in these areas must have ATEX Certification. The Certification required depends on the level of danger, classified as Zones in Europe and by the IEC and as Classes in the USA.

Current classifications are as follows:

Classification | Definition of Zone or Division |

|---|---|

Zone 0 (EU and IEC) (Gas / Vapour / Mist) Class I Division 1 (USA) (Gases) | Category 1G An explosive atmosphere consisting of a mixture with air of dangerous substances is present continuously or for long periods |

Zone 1 (Gas / Vapour / Mist) Class I Division 1 (Gases) | Category 2G An explosive atmosphere is likely to occur in normal operation occasionally |

Zone 2 (Gas / Vapour / Mist) Class I Division 2 (Gases) | Category 3G An explosive atmosphere is unlikely to occur, and if it does, is only present for a short period |

Zone 20 (EU and IEC) (Dusts) Class II Division 1 (USA) (Dusts) | Category 1D An explosive atmosphere in the form of a cloud of combustible dust in air is present continuously, or for long periods |

Zone 21 (Dusts) Class II Division 1 (Dusts) | Category 2D An explosive atmosphere is likely to occasionally occur in normal operation |

Zone 22 (Dusts) Class II Division 2 (Dusts) | Category 3D An explosive atmosphere is unlikely to occur, and if it does, is only present for a short period |

ATEX specifically refers to two EU directives, concerning the protection of workers and equipment in potentially hazardous environments.

In order to ensure the safety of products in use in hazardous environments, manufacturers and suppliers must have their products tested for conformity and certified. ByteSnap has experience in supporting customers in this – and can save you time and money on your product development.

See how we helped Geotechnical Instruments Ltd develop their intrinsically safe biogas analyser:

“Great Credentials, Proven Track Record”

Steve Earp – Project Manager, Geotechnical Instruments Ltd

THE BENEFITS OF WORKING WITH BYTESNAP

We offer experience and reliable support throughout the product and PCB or electronic board design life cycle, with both software and hardware engineers working side-by-side on projects to identify the best solution for each client.

We’re Not Just Software Engineers

Complete Solution, Team Integration

We Focus a Solution to Your Problem

Experience the Security of Consistency

Own Your End Product IP

Broad Array of Project Experience

AWARD-WINNING CONSULTANCY FOR ELECTRONICS SOFTWARE

DEVELOPMENT & HARDWARE DESIGN

For over 17 years, clients have engaged ByteSnap Design to deliver exceptional electronics for hazardous environments. We are trusted by companies across the UK and beyond, providing them with business and deep technical expertise under one roof.

How can the team at ByteSnap support your ATEX project today?

ByteSnap’s team are enabling companies to navigate the certification and design process, keeping them a step ahead. Guarantee quality and smooth your path to market – contact us today!

Zone 0 electronics design & ATEX intrinsically safe product design FAQs

What makes a PCB design intrinsically safe?

Intrinsically safe PCB designs limit electrical energy to levels below the minimum ignition energy of explosive atmospheres. This requires energy limitation circuits, certified components, and compliance with IEC 60079-11 standards. The maximum energy for Group IIC applications must not exceed 96µJ.

How long does ATEX certification take for custom electronics?

ATEX certification typically takes 8-12 weeks for well-designed products with complete documentation. ByteSnap’s pre-certification design review process reduces this to 6-8 weeks by eliminating common failure points before formal testing begins.

What considerations apply when designing for both ATEX and IECEx certification simultaneously?

Dual certification requires harmonising IEC 60079 series standards with regional variations. Key differences include ambient temperature classifications (ATEX uses -20°C to +40°C standard vs IECEx -20°C to +60°C), and explosion testing requirements.

Component certification must be recognised by both schemes. We maintain databases of dual-certified components from approved suppliers. Documentation packages require different language conventions and marking requirements for each scheme.

Can existing products be retrofitted for ATEX compliance?

Retrofit feasibility depends on the original design architecture. Approximately 40% of existing products can be modified for ATEX compliance, while 60% require complete redesign. ByteSnap’s assessment service determines retrofit viability within a few days.

What's the cost difference between ATEX and standard electronics design?

ATEX compliance typically adds 30-50% to initial design costs but eliminates redesign risks worth £75,000-£250,000. The total cost of ownership often favours ATEX-first design approaches for industrial applications.