Case Study Snapshot

- Company: Sonatest Ltd

- Profile:Manufacturer of ultrasonic Non-Destructive Testing devices for engineers inspecting a wide range of composite materials

- Size: 51-200

- Project vertical: Ultrasonic testing

- Challenge: New microcontroller used on key devices was pin out compatible hardware-wise, but required software updates

- Solution: Firmware update, testing

- Services: Firmware support; electronics integration of software

- Impact: Enhanced products as additional code space enables new features

Introduction

Sonatest was founded in 1958 and is one of the most respected suppliers of ultrasonic Non-Destructive Testing instruments in the world.

The company is internationally recognised for the quality of its rugged and portable products. Sonatest equipment is used by world-leading businesses including Boeing, Airbus, and Shell, and deployed in verticals such as power generation, oil and gas and aerospace.

Sonatest uses sonar to explore equipment for faults, acoustically ‘seeing’ through parts and creating complete volumetric integrity reports. Designed in Canada, the products are manufactured in the UK.

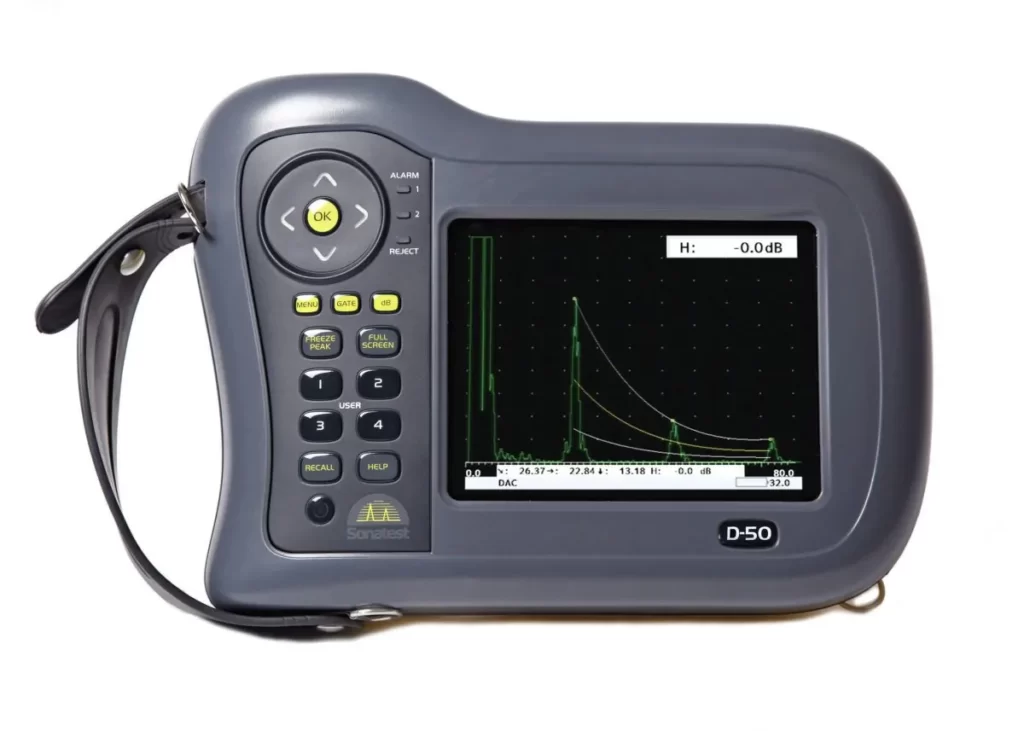

Innovation is at the heart of the company’s strategy and the Sonatest’s engineers wanted to introduce new features to its Sitescan D-50 and Masterscan D-70 range of single channel flaw detectors. They identified that the existing microcontroller within the products was no longer fit for purpose.

A new microcontroller was sourced, and Sonatest required specialist electronics services to undertake low-level firmware modification and ensure existing application software compatibility.

Challenge

The main challenges faced by Sonatest were product enhancement and limited lifespan. Sonatest had selected a new microcontroller with increased storage to host more code space for the addition of new features identified by the product team and also requested by clients.

The existing software needed to be ported to the new device without compromising its reliability and features. The system is structured so that the driver software layers fit with the application software layer. During the migration there was a risk that any incorrect change could potentially introduce subtle problems. Sonatest needed a specialist electronics company to identify and amend only the necessary files to minimize risk to the system.

The validation process required a number of physical devices which attach to the equipment along with suitable test materials to check the validity of the results. However, before that Sonatest needed some software testing services to check the basic working of the device before undertaking its own lengthy functional testing efforts.

Sonatest produced the boards and required an electronics expert to update the drivers for the new hardware. While Sonatest has manufacturing and software experience in house, the team is primarily focused on analogue projects and application software, so sought electronics engineers with low level driver experience.

Solution

Sonatest identified ByteSnap as an Approved Engineering Consultant for NXP Semiconductors and selected the consultancy for its knowledge of and experience with the NXP K66 processor and the MQX OS, Midlands location and transparent pricing.

ByteSnap engineers thoroughly examined the code base and schematics to determine differences using the new microcontroller. It was determined how much software needed updating and whether there were missing features between the old and new parts. There were minor differences found which Sonatest confirmed were not used in the current product and would not impact the system.

Sonatest had populated a number of PCBs with the new microcontroller, but to test these required porting of the code. The project was undertaken in two phases:

- the development of a bootloader to test the basic chip features

- the main application changes

The ByteSnap experts migrated the software running to the new CPU, modifying the existing codebase where necessary and ensuring that there was no loss in functionality.

At the onset of the project, it was unclear how as to how long it would take to complete all the tasks. The codebase of the project was extensive as it covered many complex features on a number of products in the Sonatest range.

ByteSnap offered a flexible cost model with estimated project timescales given the investigation so far. Progress was clearly communicated throughout the development cycle. The project was completed and delivered within the original time and budget estimates.

Benefits

ByteSnap’s work delivered several benefits to Sonatest, including:

- Increased lifespan of products for another five – six years

- Introduced the ability to add more features to Sonatest’s key products due to increased code space

- Minimum changes and no need to upgrade application software

- Speedy project completion with expected results delivered ahead of deadline

- Transparent and clear pricing

- Work delivered by an experienced and highly knowledgeable team